Initial situation

A female patient, age 52, sought dental care with the aim of replace the upper removable prosthesis. (Figs. 1-2). The patient was unsatisfied with the low retention and aesthetics. The patient requested an immediate and fixed option to improve masticatory function.

Procedure

Treatment planning

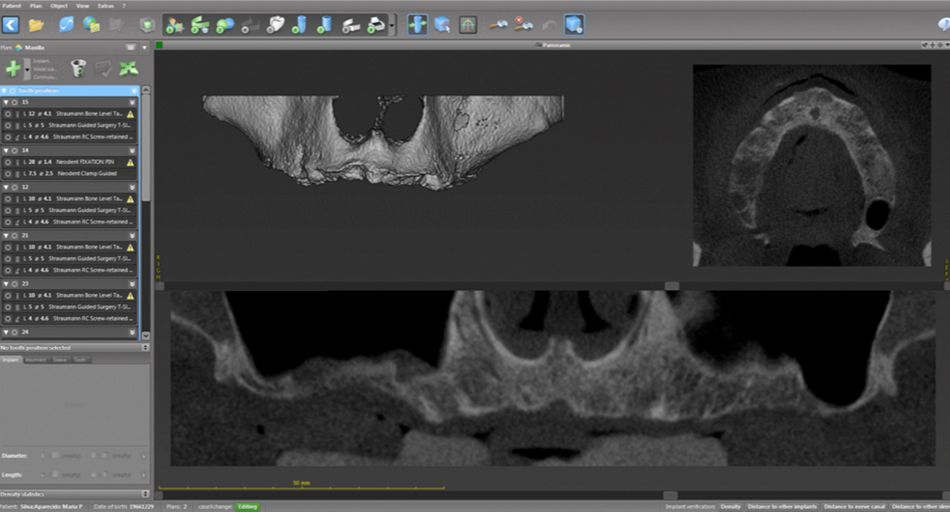

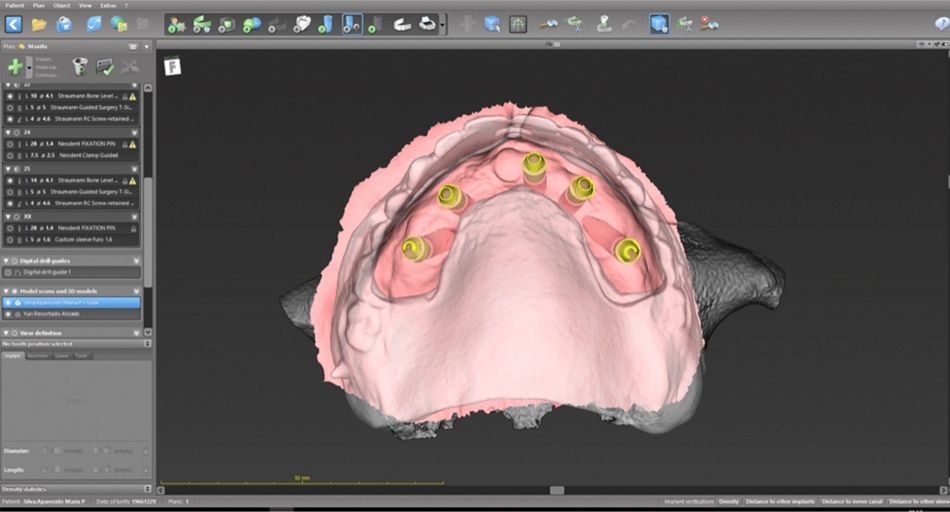

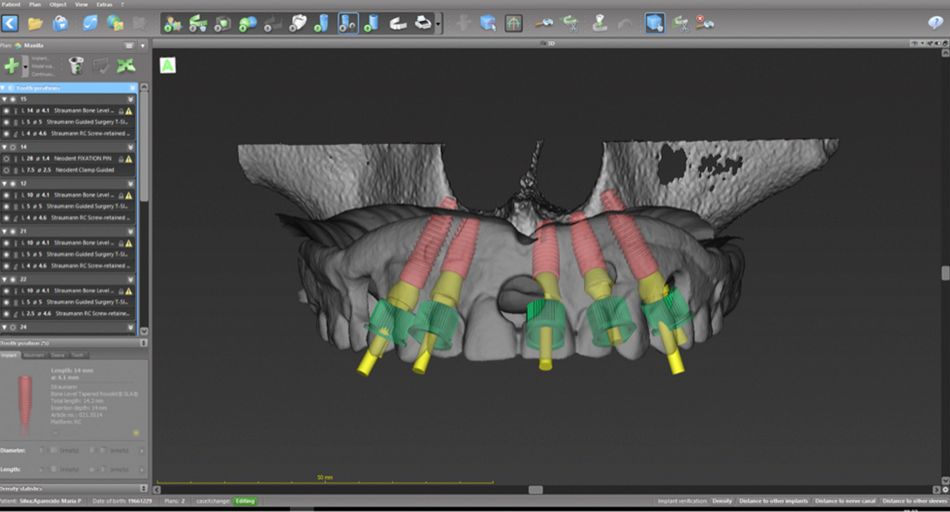

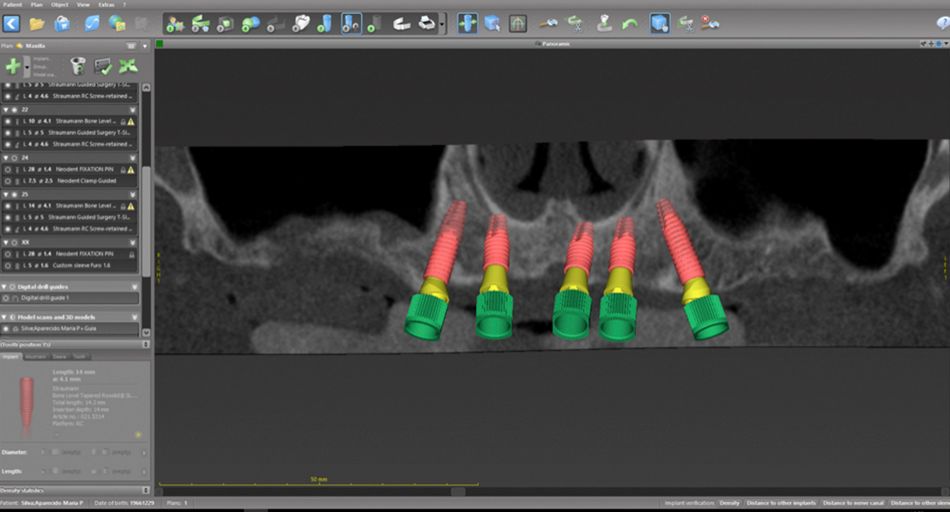

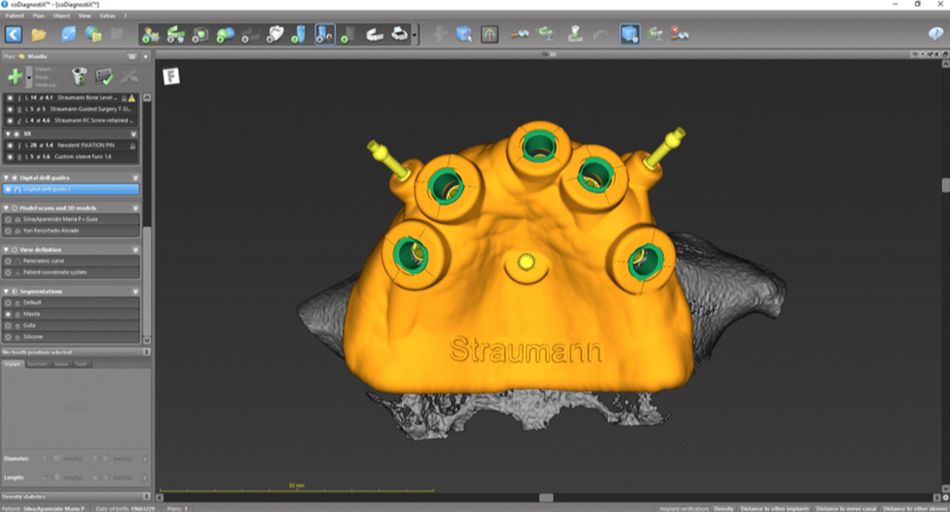

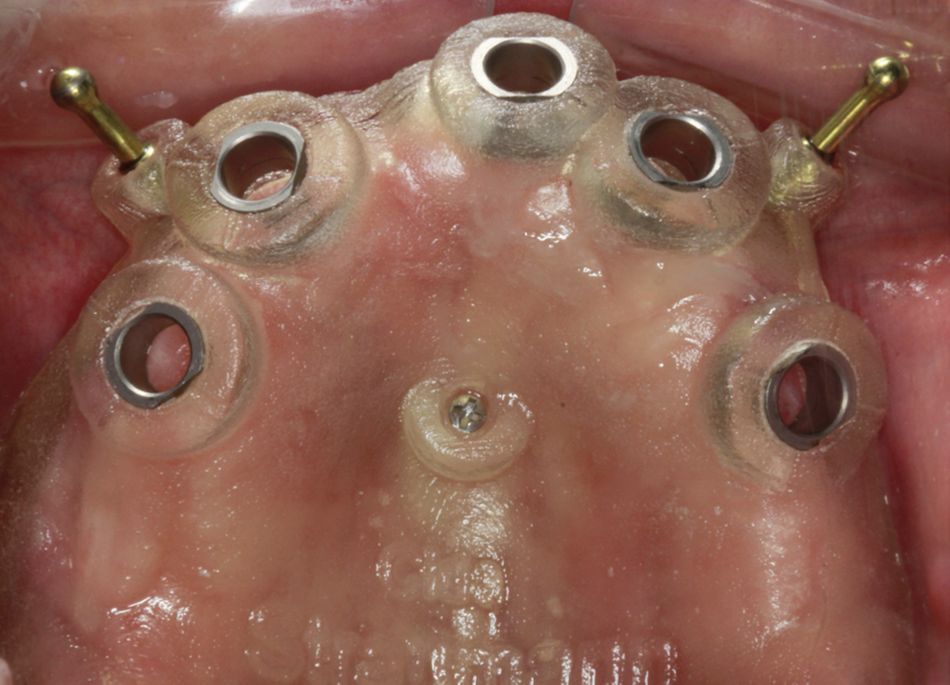

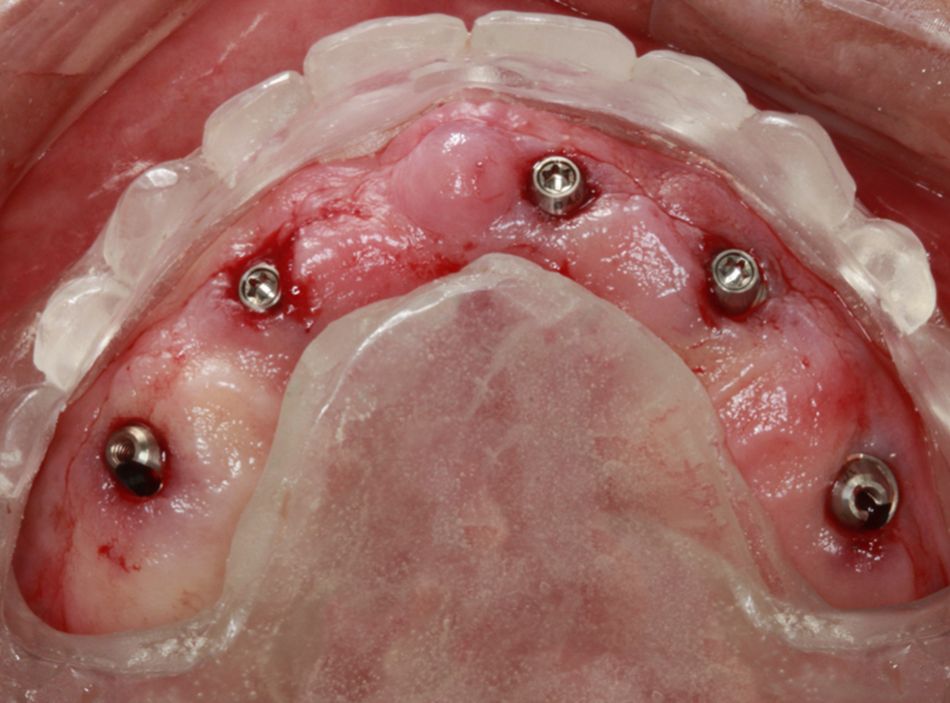

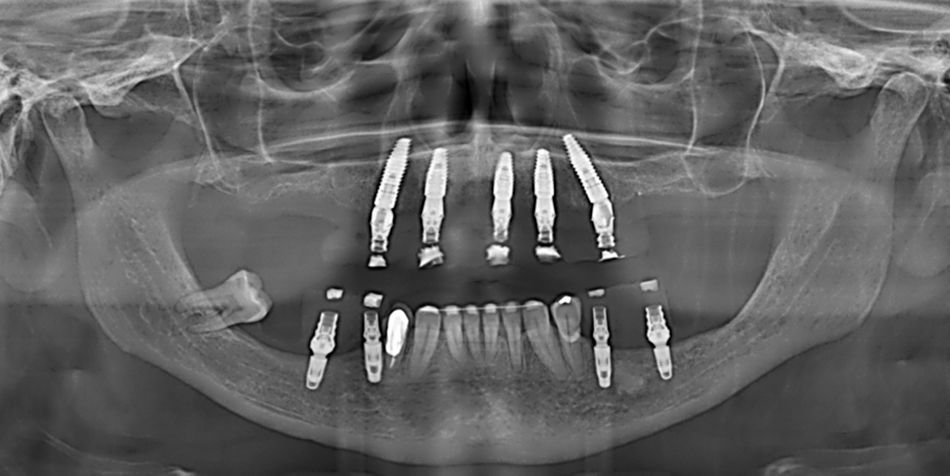

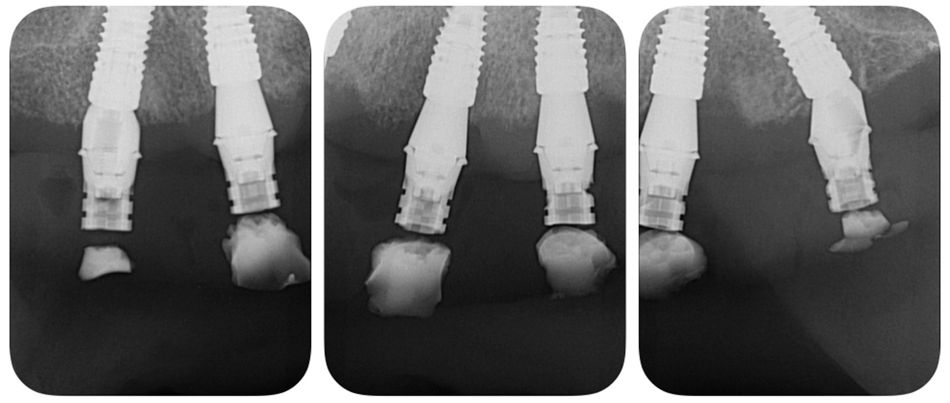

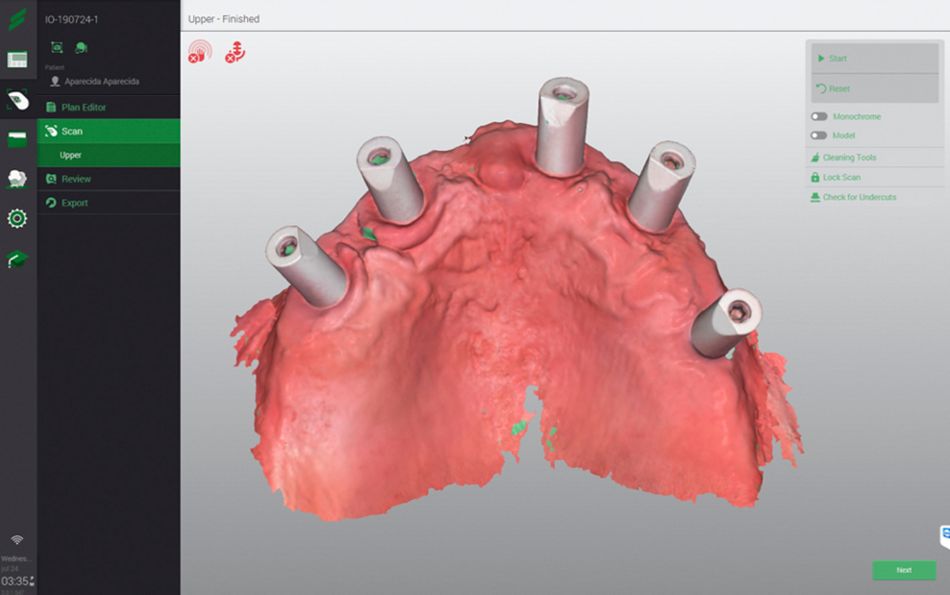

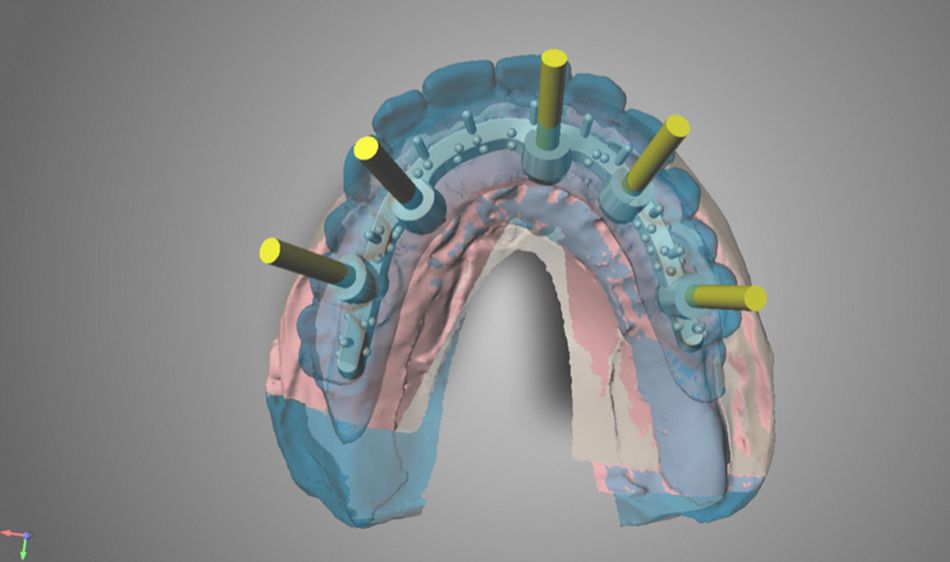

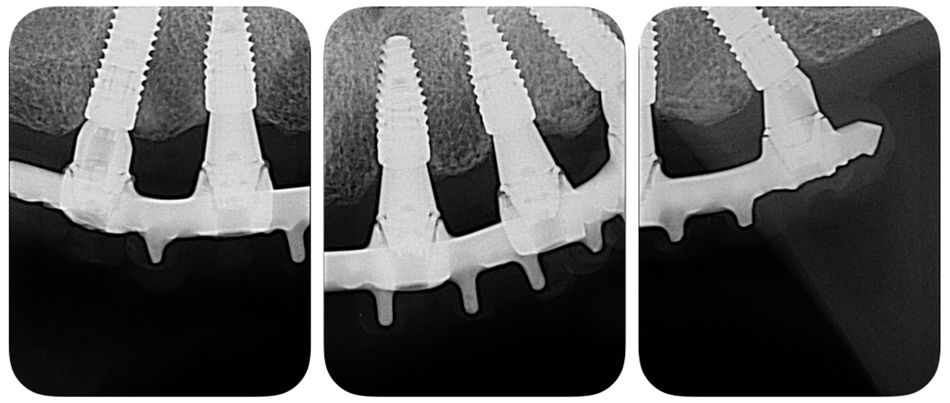

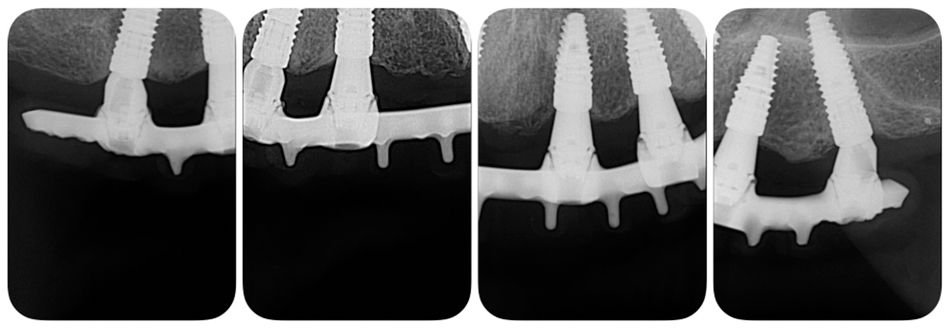

The initial treatment plan involved the placement of BLT Straumann® dental implants to support an upper fixed hybrid prosthesis. The patient was referred for computed tomography using a double scan protocol with coDiagnostiX™ (Dental Wings, Chemnitz, Germany) (Figs. 3-5). The strategy of the virtual planning was to circumvent the right and left maxillary sinus with tilted and long implants and seek apical anchoring in the lower cortex of the nasal fossa, using a predictable, simple and accessible procedure for the patient, following the Straumann® Pro Arch concepts. The drill guide was designed and exported for 3D printing, being a tool to improve the positioning of the implants (Fig. 6).

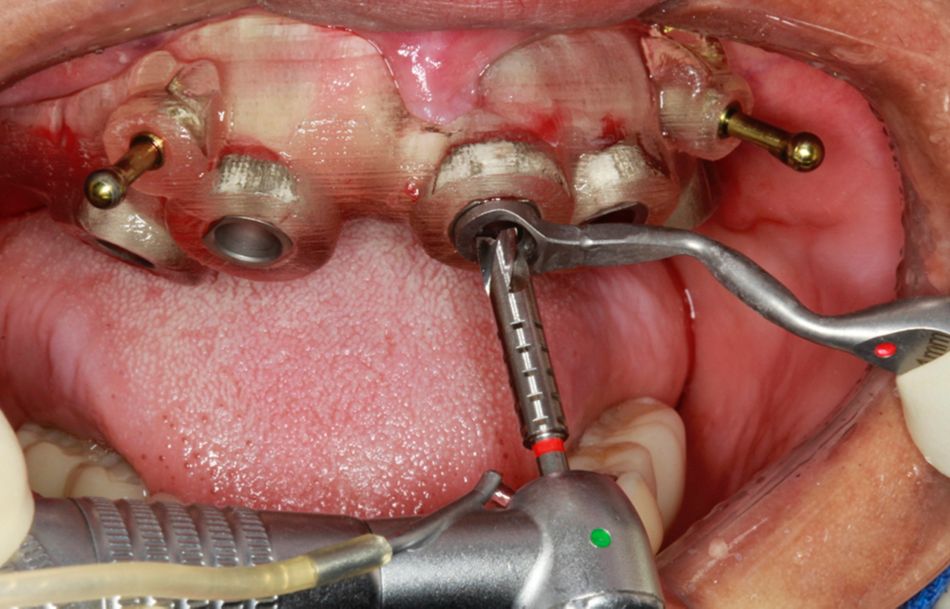

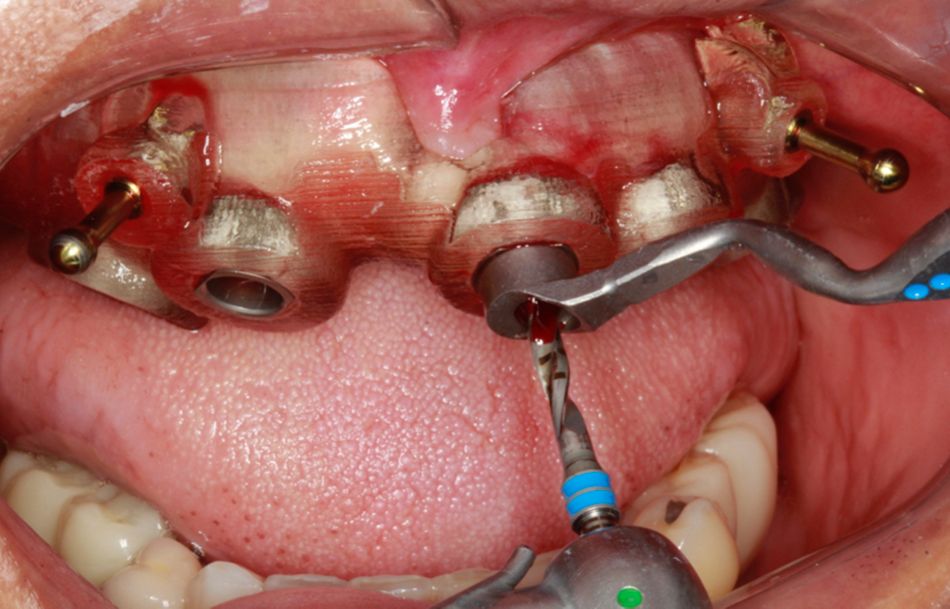

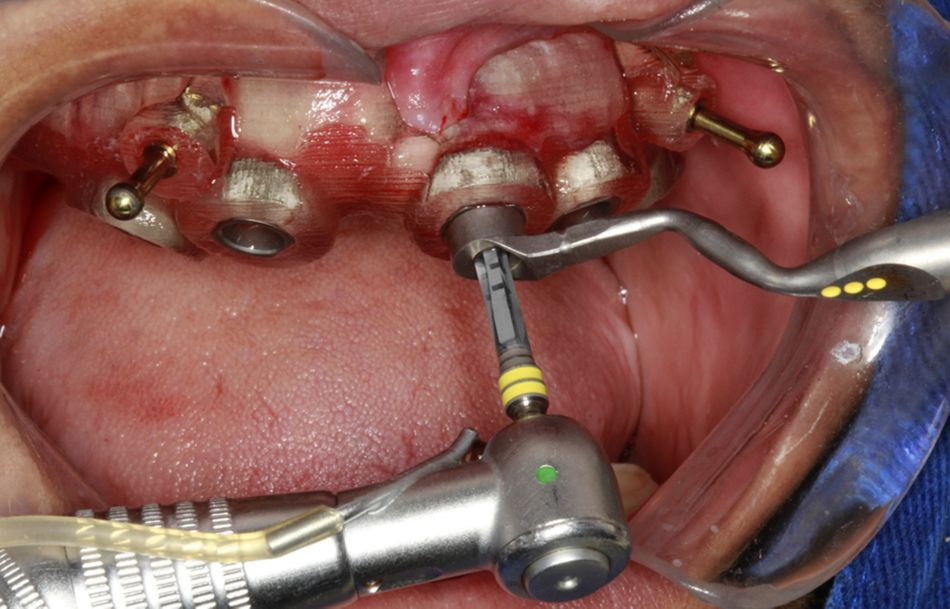

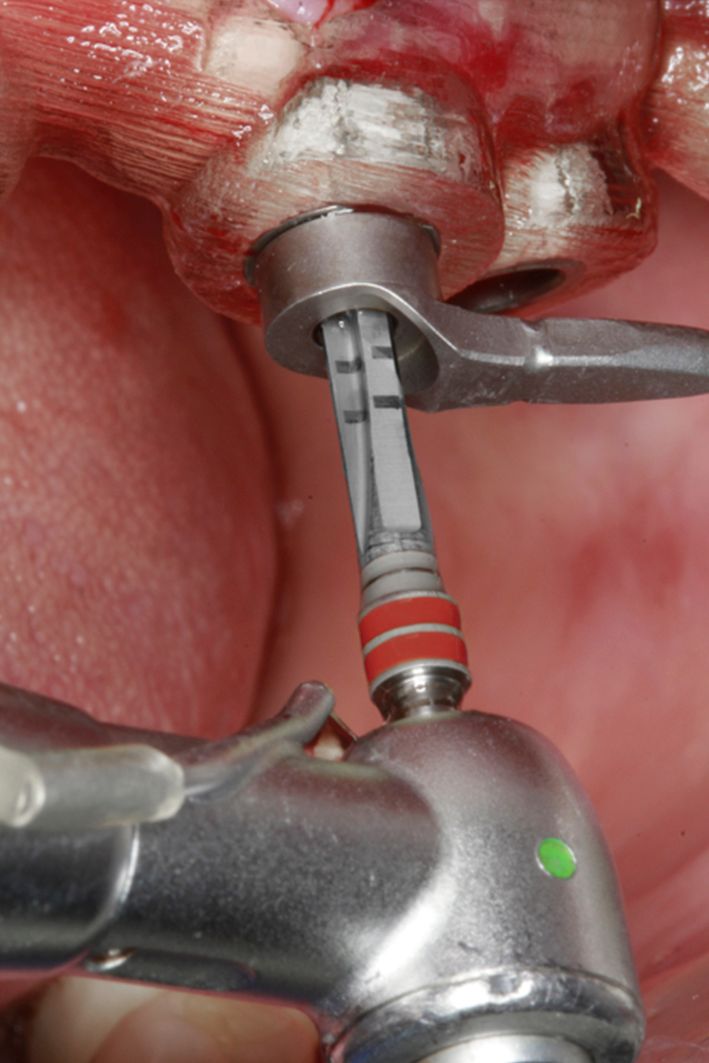

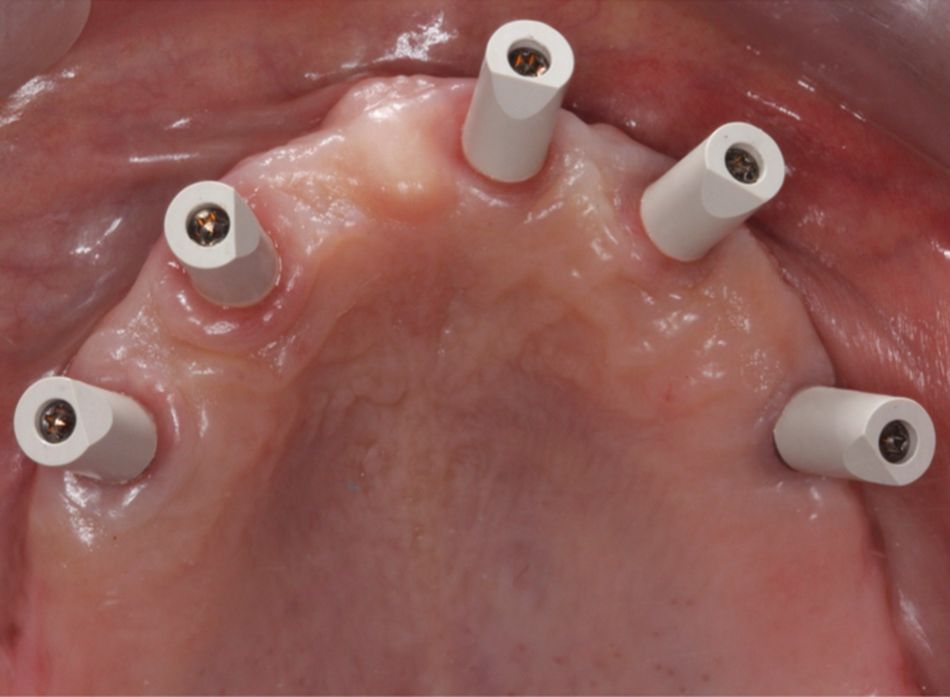

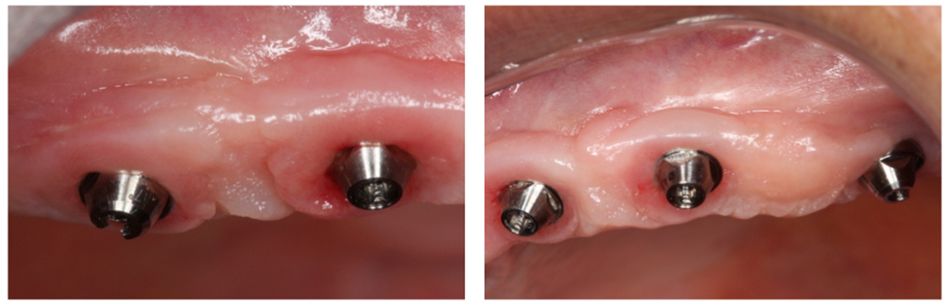

Surgical procedure