Reliability, endurance, low maintenance and high patient comfort

F.A.Q.

The Straumann® Novaloc® Retentive System for hybrid dentures offers an innovative carbon-based abutment coating (ADLC, amorphous diamond-like carbon) with excellent wear resistance, overcoming up to 60° implant divergence. Both a straight and a 15° angled abutment, available in various gingiva heights, cover a broad range of clinical implant situations. Together with its durable PEEK (Polyether ether ketone) matrices, the Novaloc® Retentive System provides a reliable connection that endures, which results in low maintenance and high patient comfort.

Straumann® Novaloc retentive system for hybrid dentures – why?

Every new Straumann product must serve a very specific purpose: it must provide our customers with clear added value – for example in terms of handling or additional indications, thereby providing their patients with the best possible experience with their implant-based solutions. The key words when it comes to hybrid dentures are maintenance and longevity. The former should be minimized and the latter maximized. This interests and affects everyone involved: the dentist fitting the implant, the dental technician and, of course, the patient. The Novaloc® Retentive System is specifically designed to satisfy these requirements.

What properties does Novaloc® offer?

In a nutshell: thanks to its surface texture, the Novaloc® abutment offers unmatched wear resistance, thereby facilitating durable, reliable use in challenging indications. The matrices are made of PEEK (polyether ether ketone), a biocompatible high-performance polymer with excellent properties in terms of mechanical and chemical resistance.

What exactly is the correlation between surface roughness and longevity in the context of hybrid dentures?

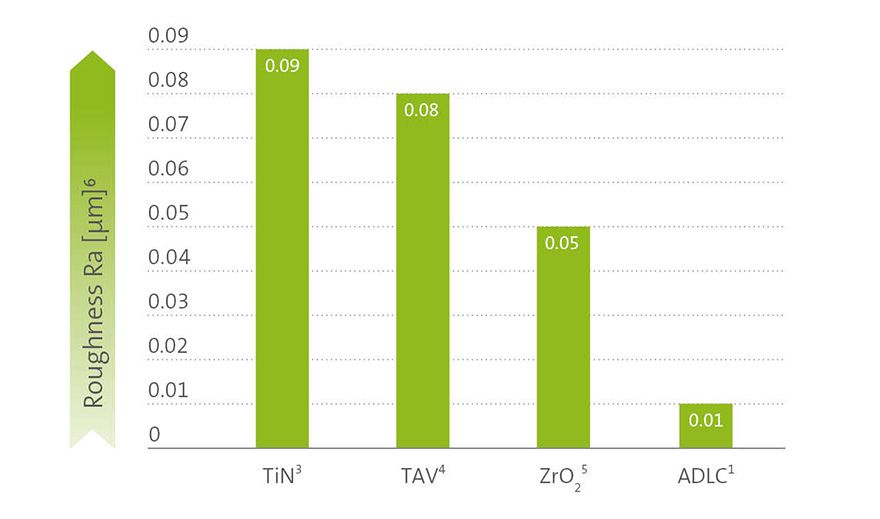

The obvious correlation is that a smooth abutment surface is less abrasive against the retention inserts and thus contributes to longevity. The comparison between the physical properties of various coatings underlines the high performance of our ADLC-coated abutment (ADLC = amorphous diamond-like carbon). The roughness of a surface area is indicated by the roughness parameter Ra. The smaller this parameter, the smoother the surface. ADLC, the surface coating used for the Straumann® Novaloc® Retentive System, has shown an Ra of 0.01 in tests, i.e. up to 9 times lower than the values determined for other abutments used in hybrid dentures (see figure below). Expressed as a percentage: the roughness of Novaloc® is 89% lower than that of titanium nitride1.

The ADLC coating of the new Novaloc® retentive system – a really fascinating material

DLC stands for “Diamond-Like Carbon” and exists in various forms that come with some of the typical properties of a diamond – hardness, wear resistance and a sleek surface – which in turn forms the basis for longevity. ADLC is one of these manifestations, in chemical terms a-C:H. So we have amorphous carbon presenting a mixture of graphitic sp2 and sp3 bonded carbon atoms2. DLC is already broadly used in the medical device industry but, to our knowledge, has not been used for a dental abutment to date.

One of the most obvious aspects of the Straumann® Novaloc® Retentive System: its color. Why is it so and are other colors available?

You can have any color you want, as long as it’s black – to quote Henry Ford. Seriously, the specific color is determined by the carbon-based coating and its molecular composition.

Why is there also an angled abutment?

The angled insertion of an implant may be required, for example, in cases where only a small amount of bone is available. Where straight abutments approach their limits, the angled abutment is the ideal solution in such situations. It provides a common insertion axis for the prosthesis, reduces unilateral loading of the abutments and ultimately provides the patient with an agreeable experience in terms of implant integration.

Who is the Novaloc® retentive system aimed at?

For all the reasons outlined above, it can be concluded that the Novaloc® system is actually aimed at anyone who works with hybrid denture solutions: clinicians, dental technicians and, last but not least, patients – they all benefit from low levels of maintenance and hassle, resulting in greater comfort and thus a better quality of life for the patient.

1. In internal roughness tests titanium nitride (Tin) showed an Ra of 0.01 (data on file). 2. Sp2 carbon bonds describe a trigonal-planar molecular structure, like that in graphite, whereas sp3 corresponds to the tetrahedral structure found in diamonds.

APPENDIX

The comparison between the physical properties of various coatings underlines the high performance of the ADLC (amorphus diamond-like carbon) abutment coating. Clinicians, dental technicians and more importantly patients benefit from: less maintenance, less hassle and therefore more comfort. The chart below shows the different surface roughness (Ra) values of retentive abutments for hybrid dentures (data on file). The roughness of a surface area is indicated by the roughness parameter Ra – the smaller the parameter value the smoother the surface. A smooth abutment surface is less abrasive against the retention inserts and contributes to longevity.

Novaloc® is a registered trademark of Valoc AG, Switzerland. For availability information in your country contact your official Straumann representative.